The Drum Buffer Rope (DBR) approach is a management tool used in the Theory of Constraints and follows the five focusing steps when assessing a physical process. With a physical process there exists and input, an output, and interrelations between work cells or departments. DBR provides a means to manage the throughput in pursuit of achieving 100% due date performance.

The Drum in DBR.

The Drum is simply the constraint of the process. It sets the beat of the system and is used as your single point of control. In many cases the constraint will be obvious, but as it is elevated it is possible for it to move. Lets say a machine shop has a specific machine as the constraints, once identified DBR can be put in place. If that machine shop however decides to purchase another one of the constraint machines and doubles the capacity at that location, it is quite possible the constraint could move. If this happens, the new Drum must be identified in order to continue managing according to the constraint.

Having the ability to move the Drum means that an organization can strategically place the drum in any location they choose. This can be greatly advantageous depending on the plant type. An “I” style plant can have a number of locations that would work for the constraint and location will depend on specifics of each plant.

“V”,”A”, and “T” style plants on the other hand have optimal points of control.

A “V” style plant would be one that often starts from a single raw material and produces many parts. A foundry, or an injection mold facility may fit this plant type well. In any case, the location for the constraint is best suited at the base of the “V”. If the base of the “V” can be controlled, and all aspects beyond the vertex have excess capacity one could expect exceptions due date performance.

Plants that follow more of an “A” flow would look as follows

The Drum in this case is again at the vertex, but the vertex is now the last point of the process. With an “A” plant one only wants the work in progress to be that for orders placed. Taxing the system with anything other than orders received puts a load on the system as a whole that will decrease the due date performance. Coordinating assembly efforts, and accounting for variability before the Drum may be a task in itself but the best results will come with the Drum at the top. The buffer in this case may be a shipping buffer which contains finished products.

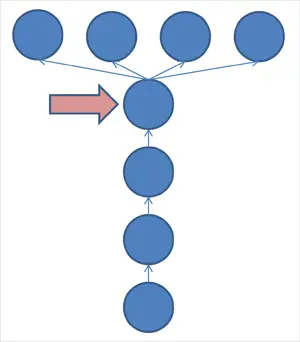

The last flow style I will touch on is the “T” style plant. The Drum in a “T” plant is best placed at the T.

This could be a plant that customizes their product to fit personalized requests. Much of their products are the same but require a quick modification at the end of production to make them ready for a specific customer. A wooden sign shop would be a good example.

The Buffer in DBR.

The Buffer is put in place to insure that the Drum always has work to do. Additional buffers are often incorporated throughout the process but the original Buffer was put in place to protect the Drum. It is not uncommon to see material buffers, assembly buffer, and shipping buffers in a fully integrated DBR solution.

Buffers are required to account for the variability that will no doubt show up. Machines break down, people get sick, and sometimes it snows. Having strategic buffers will minimize dependences that may disrupt the production process. Placement of buffers will change with plant flow just as the Drum placement did.

The Rope in DBR

The Rope is the release timing mechanism that informs prior processes when to start producing. It is the pull if you will of down line operations to up line operations. The Rope operates in real time and signals for material as it is consumed. The Rope is what allows the release of material to stay in sync with the Drums production. This is similar to Kanban.

Simplified Drum Buffer Rope (S-DBR)

Simplified Drum Buffer Rope came out of a need to address the system when the market is the constraints. When the market is the constraint the DBR approach can be simplified to having the Drum be the orders from the customers, a shipping buffer at the end of the process, and the Rope is also dictated by the demand of the market. In other words the internal capacity is greater than that of the market. The goal is to meet the needs of the market as they exist. The S-DBR approach allows the company to fulfill instant demands as well as longer lead orders.

Leave a Reply